Digital Fabrication for Designers CNC Cut Wood Joinery

203 - Invisible Panel Joints. Whenever I glue multiple boards together, my ultimate goal is to hide the fact that it is indeed a glueup. If I can make it appear as if the panel was cut from one super wide board, I'm a very happy boy. The first step in achieving this lofty goal is to make sure the edges are milled properly.

Pin on Joinery Detail

3. Coped joint. A coped joint is a variation on the miter joint that lays underneath the miter joint. It addresses the reality that the corners of many rooms do not in fact meet at 90-degree angles. Beneath the exterior (visible) miter joint, the two pieces of wood that make up a coped joint are carved like puzzle pieces to form an irregular but custom fit.

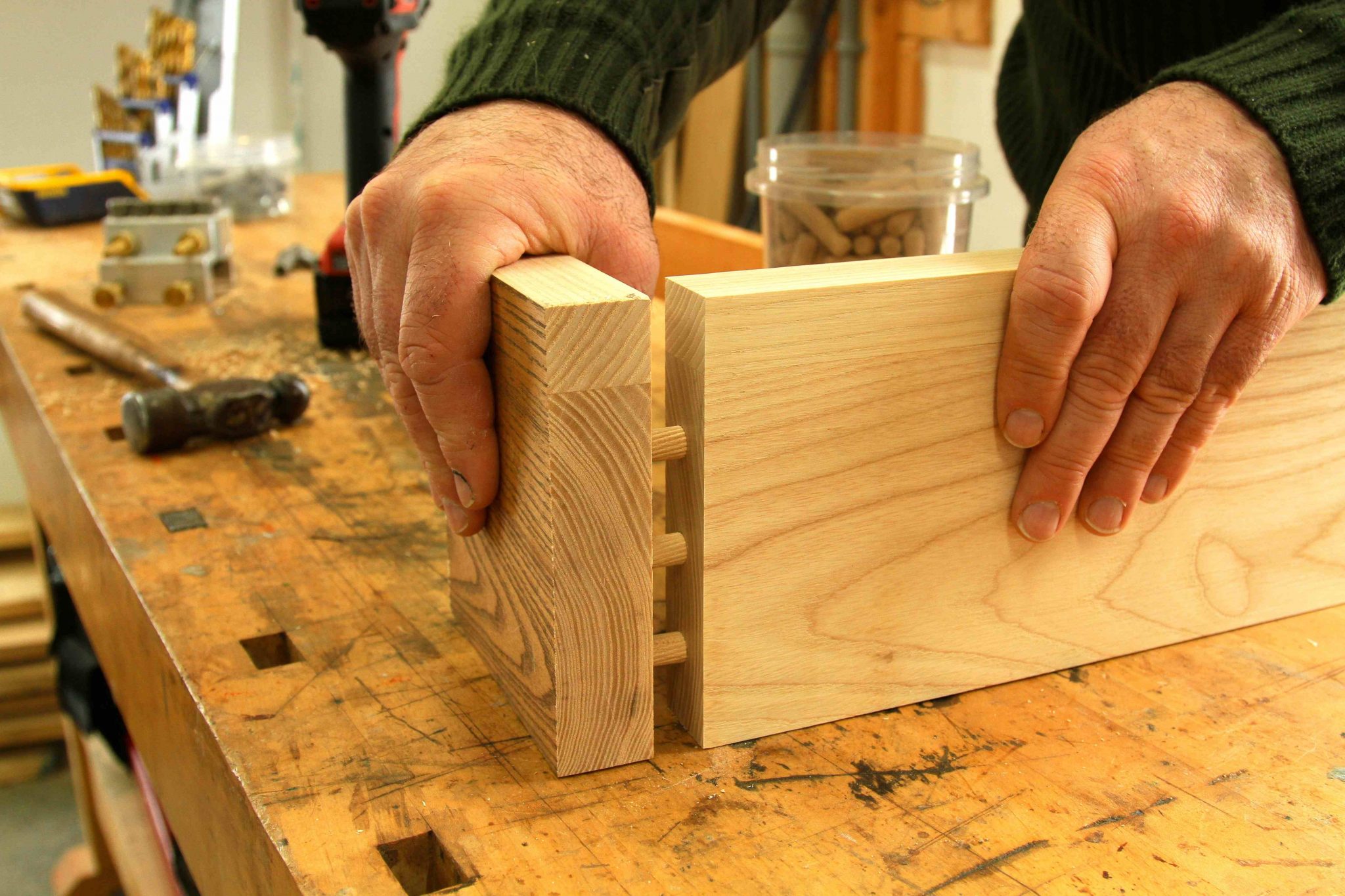

DOWEL JOINERY Why It's Easy to Love This Great Woodworking Technique

Level of Complexity: BEGINNER. Another simple technique is using dowels to strengthen butt joints. Wooden dowels have reinforced furniture joints for many years and are used to help maintain alignment during glue-ups as well. A dowel can also replace stripped fasteners to remove play in butt and miter joints.

Woodworking Different Types Joints ofwoodworking

It is usually used when a connection needs to be made in the middle of the wood. Half-lap joints are often used in both manufacturing furniture and framing. Fig 3:Half-Lap Joint. 4. Tongue and Groove Joint. The tongue and groove joint is another famous woodworking joint used in wood flooring, parquetry, paneling, etc.

Joining wood panels Woodworking joints, Wood diy, Woodworking

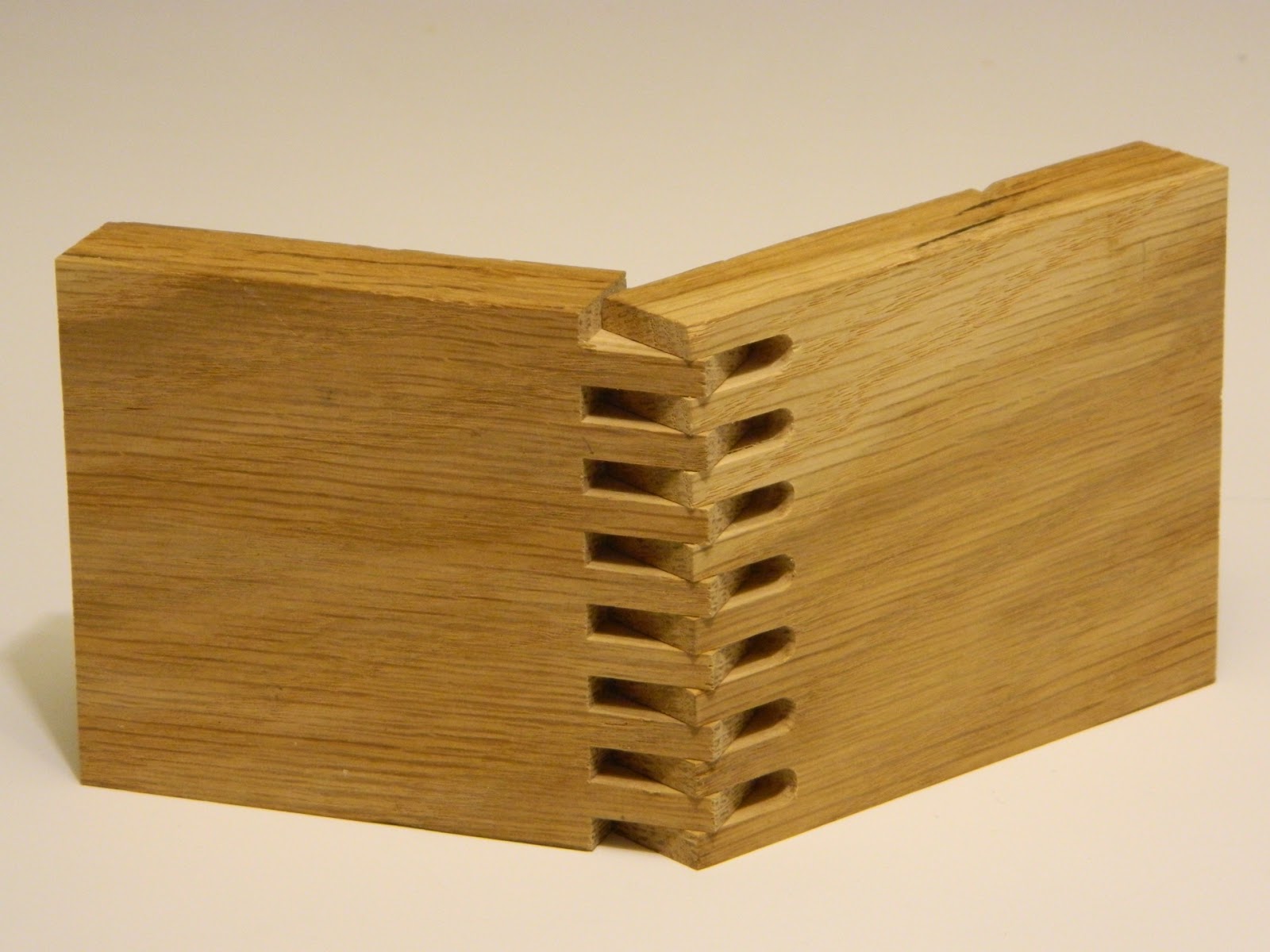

THE DOVETAIL JOINT. Dovetail joints are very strong and resist pulling apart through the use of wedge-shaped interlocking pieces (the wedges resemble a dove's tail). Dovetail joints are found.

Table with 45 degree corner groove Woodworking joints, Woodworking joinery, Diy woodworking

Procedure. Place the joining machine at the front edge of the workpiece with the stop pin for the first routed hole, and route the hole with the appropriate hole width. +. For the other routed holes, set the desired hole distance on the cross stop and position the pin in the first routed hole. Route the other holes as slots.

Wood Joints 4 Types of Joinery Options to Use Family Handyman

Uses: This type of wood joint is often used in furniture making and crafts. Your table legs are most probably joined by a stopped mortise and tenon joint and the chair legs are often attached with the help of angle mortise. 9. Rabbet Joint. Woodworkers form this joint by forming a recess into the edge of the timber.

Frame And Panel Finesse Carpentry and joinery, Wood joinery detail, Joinery design

Japanese Wood Joints. Japanese wood joints, also known as Kumiko, build traditional Japanese houses. In this technology, the grooved wood pieces are joined together to create a sturdy tree dimensional structure.. Paneling: Tongue and groove paneling can create a traditional, rustic, or modern look in a room. Cabinets: Used in cabinet.

Basic Wood Joinery YouTube

Box joints have parallel cuts and open visible joints. An alternative to the dovetail joint, they are used for box corners or box-like constructions. One advantage of using a box joint is that it is easy to make and can be easily mass-produced. This type of wood joint is suitable for joining wide slats, boards, and solid wood panels. #14.

Finger joints Wood joinery, Woodworking, Wood

Then adjust the depth of the cut to be exactly half the thickness of the stock. This cut needs to be dead-on, so use the extra stock you surfaced to test it. Once you have that right, simply rout the tiny rabbets into the edge of your stock. For the pieces of wood in the center of the panel, rout the rabbets on the opposite faces of the wood.

The Ultimate Wood Joint Visual Reference Guide — MICHAEL TOBIN PRINCE

Wood joints are more commonly used to secure picture frames, furniture, and wood flooring, among others. But, different woodworking projects require specific types.. Making solid panels of wood; Joining wider slates #15: Dowel Joint . Dowel joints are known to be very strong and attractive joints. It is a common joint used in factory-made.

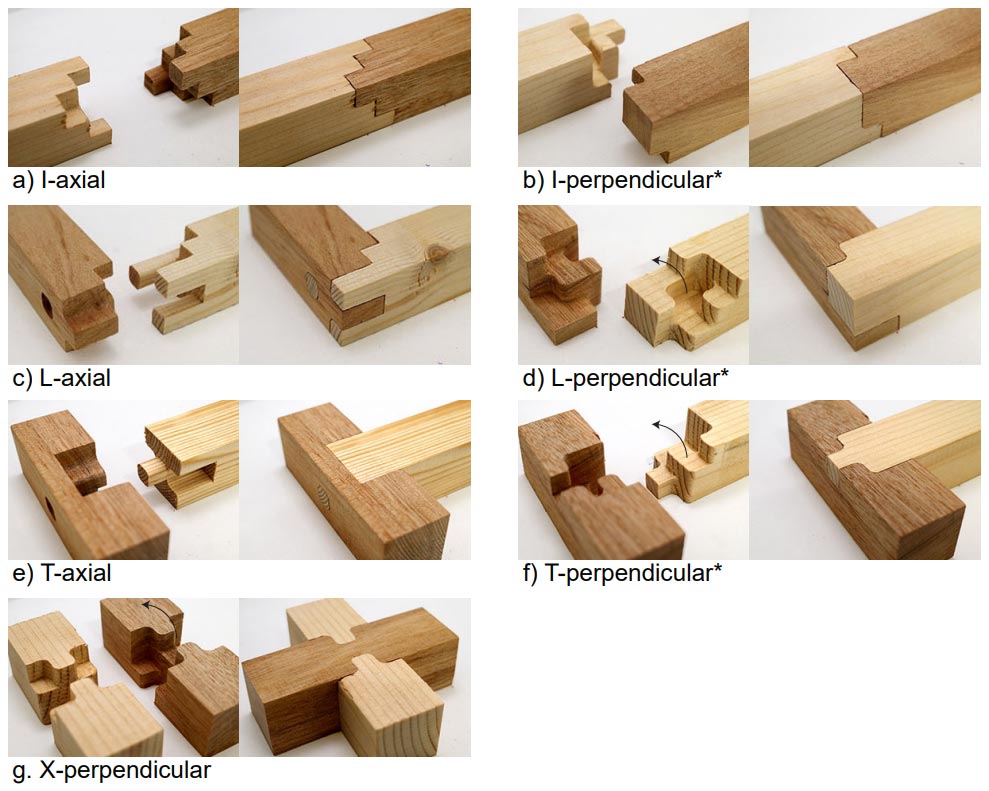

4D Furniture Thoughts Creative CNC Joinery, and Other CNCCut Solutions.

Half-Lap Joint. Chris Baylor. The half-lap joint is where half of each of the two boards being joined is removed so that the two boards join together flush with one another. This type of wood joinery can obviously weaken the strength of the two adjoining boards, but also is a stronger joint than butt joints.

The 25+ best Woodworking joints ideas on Pinterest Wood joints, Wood joinery and Joinery

Position a doweling jig over the marks, and drill holes 1 ⁄ 16 " deeper than half the dowel length. On one piece, spread glue within the holes, insert the dowels, and clamp it to a flat surface. On the other piece, glue the end grain and holes, force the pieces together, and clamp until dry.

Simple Software Creates Complex Wooden Joints That Interlock With No Nails, Glue, or Tools Needed

A finger joint, also known as a comb joint, is a common type of structural joint that connects two pieces of wood together. They are used in a variety of projects, from furniture to home decor, but are most often used to create large wood panels that are stable and robust. We have solid oak worktops in our kitchen which have been manufactured.

Common Types of Wood Joints You Should Know • 1001 Pallets

To make a mitered butt joint, cut the edge of the wood at a 45 degree angle. To fasten the two pieces together, add glue and clamp until the glue dries. 4. Tongue-and Groove Joint. A tongue and groove wood joint is often used instead of edge to edge butt joints and it easily allows for one piece of wood to slide into another.

Wood Joints And Their Uses Image to u

Drilling with the two inside guides spaces holes 1 1/4" apart. A 1/16" countersink keeps the hole edges from swelling and pushing the joint apart. Then glue and insert dowels into either the stiles or rails. Glue the exposed dowels and joint surfaces, tap the parts together, and clamp the joints for one hour.